Phased array is a technology that is based on ultrasonic testing where ultra-high frequency sound waves

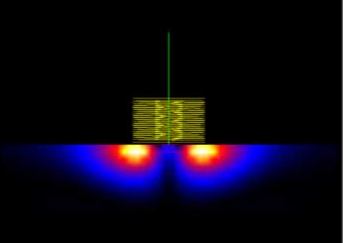

The PA probe consists of many small ultrasonic elements, each of which can be pulsed individually. By varying the timing, for instance by pulsing the elements one by one in sequence along a row, a pattern of constructive interference is set up that results in a beam at a set angle. In other words, the beam can be steered electronically. The beam is swept like a search-light through the tissue or object being examined, and the data from multiple beams are put together to make a visual image showing a slice through the object As can be seen by the second image – there is an area at the surface that is not visible to the instrument. If the Ultrasonic signal cannot be tuned to be sensitive to the area at the material surface – therefore there is a dead band for detection at the material surface.

Phased array is performed through a couplant – so some lubricant can act as a couplant in the inspection process. This is the same technology used for imaging in medical situations such as in-utero scanning during pregnancy.

(images and some text courtesy of Wikipedia)

For mechanical inspection for evidence of fatigue cracking, the benefits of a sectional cut through the machine component is limited. The maximum tensile stress is usually present at a machine component surface particularly when the component is subject to cyclical bending stresses Which gear teeth naturally are.